Contact Us

Address: Anjiazhuang Industrial Park Of Jinzhou City, Hebei Province, China

Tel / WeChat: +86-13832332178

Tel: +86 311 84396930

Email: sales@hanformwork.com

Whatsapp: +86-15097331922

Scaffold Forged Coupler

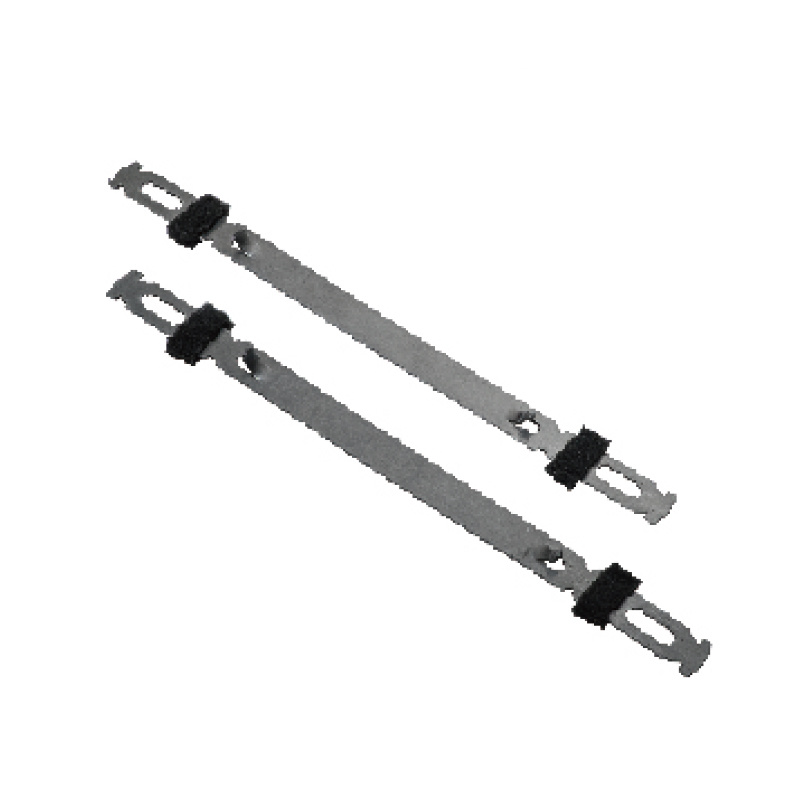

- Commodity name: Scaffold Forged Coupler

- Product Description

-

Scaffold forged couplers play a crucial role in the construction industry, providing stability and safety for scaffolding structures. These couplers are designed to connect and secure scaffold tubes, ensuring a strong and reliable support system for workers and materials. In this article, we will explore the importance of scaffold forged couplers, their various types, and their key features.

Types of Scaffold Forged Couplers

There are several types of scaffold forged couplers available in the market, each with its own unique features and applications. The most common types include swivel couplers, right-angle couplers, putlog couplers, and sleeve couplers. Swivel couplers are used to connect two scaffold tubes at any angle, providing flexibility in scaffold design. Right-angle couplers are used to join two tubes at a right angle, creating a sturdy and stable connection. Putlog couplers are used to secure putlogs or transoms to the main scaffold tube, while sleeve couplers are used to extend the length of scaffold tubes.

Key Features of Scaffold Forged Couplers

Scaffold forged couplers are made from high-quality steel and are designed to withstand heavy loads and harsh weather conditions. They are heat-treated to ensure maximum strength and durability, making them ideal for use in construction sites. The couplers are also designed to be easy to install and remove, saving time and labor costs. Additionally, they are corrosion-resistant, ensuring a long service life and reducing the need for frequent replacements.

Importance of Scaffold Forged Couplers

Scaffold forged couplers are essential components of scaffolding systems, providing a safe and reliable support structure for workers and materials. They help to distribute weight evenly across the scaffold, preventing collapses and accidents. Couplers also ensure that scaffold tubes are securely connected, reducing the risk of dislodgment or instability. By using high-quality forged couplers, construction companies can improve the safety of their workers and enhance the efficiency of their projects.

Safety Considerations

When using scaffold forged couplers, it is important to follow safety guidelines and regulations to prevent accidents and injuries. Workers should be properly trained on how to install and remove couplers, as well as how to inspect them for damage or wear. Couplers should be checked regularly for signs of corrosion or deformation, and damaged couplers should be replaced immediately. Additionally, couplers should be installed according to manufacturer's instructions and should not be overloaded beyond their capacity.

Conclusion

Scaffold forged couplers are essential components of scaffolding systems, providing stability and safety for construction projects. By understanding the different types and features of couplers, as well as following safety guidelines, construction companies can ensure the safety of their workers and the success of their projects. With the right couplers in place, scaffolding structures can withstand heavy loads and harsh conditions, providing a strong and reliable support system for workers and materials.

Key words:

Get A Quote

NOTE: Please leave your email, our professional person will contact you asap!

Related Products