Contact Us

Tel / WeChat: +86-13832332178

Tel: +86 311 84396930

Email: sales@hanformwork.com

Whatsapp: +86-15097331922

Address No.1: Anjiazhuang Industrial Park Of Jinzhou City, Hebei Province, China

Address No.2: Room 1517, Building B, Xinhezuo Square, Xinhua District, Shijiazhuang City, Hebei Province, China

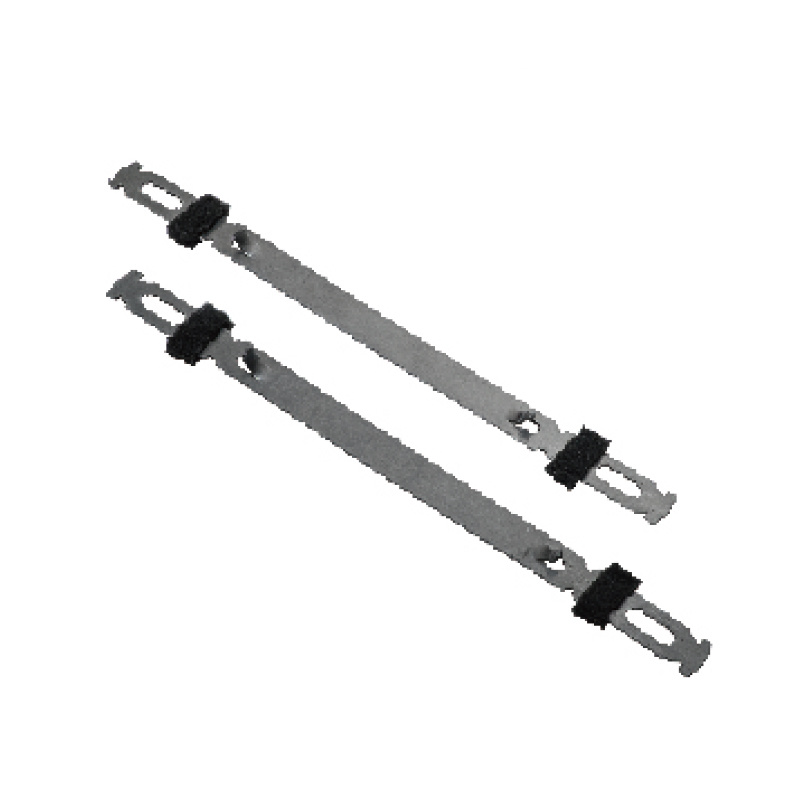

Sleeve Coupler

- Commodity name: Sleeve Coupler

- Product Description

-

Sleeve couplers are an essential component in construction and scaffolding industries. They are widely used to connect two scaffold tubes together, providing stability and support for the structure. In this article, we will discuss the importance of sleeve couplers, their various types, and how they are used in construction projects.

Types of Sleeve Couplers

There are several types of sleeve couplers available in the market, each designed for different purposes. The most common types include swivel couplers, right-angle couplers, putlog couplers, and sleeve couplers with base plates. Swivel couplers allow for the connection of two tubes at any angle, making them versatile and easy to use in a variety of configurations. Right-angle couplers are used to form right angles between two tubes, providing stability and support for the structure. Putlog couplers are used to connect putlogs to ledgers, while sleeve couplers with base plates are used to secure the scaffold to the ground.

Importance of Sleeve Couplers

Sleeve couplers play a crucial role in ensuring the safety and stability of scaffolding structures. They help to securely connect multiple tubes together, preventing them from slipping or moving during construction activities. Without sleeve couplers, scaffolding structures would be prone to collapse or instability, putting workers at risk of injury. By providing a strong and reliable connection between tubes, sleeve couplers help to create a safe working environment for construction workers.

How Sleeve Couplers are Used

Sleeve couplers are used in a variety of construction projects, including building renovations, bridge construction, and high-rise buildings. They are typically attached to scaffolding tubes using bolts or pins, ensuring a secure connection between the tubes. Sleeve couplers are easy to install and remove, making them a versatile and convenient solution for connecting scaffold tubes. They can also be adjusted to different angles and configurations, allowing for flexibility in construction projects.

Benefits of Sleeve Couplers

There are many benefits to using sleeve couplers in construction projects. They are durable and long-lasting, providing a reliable connection between scaffold tubes. Sleeve couplers are also easy to install and remove, saving time and labor costs on construction sites. Additionally, sleeve couplers are versatile and can be used in a variety of configurations, making them a flexible solution for different construction needs. Overall, sleeve couplers are an essential component in ensuring the safety and stability of scaffolding structures.

Conclusion

In conclusion, sleeve couplers are a vital component in construction and scaffolding industries. They provide a strong and reliable connection between scaffold tubes, ensuring the safety and stability of construction projects. With various types available, sleeve couplers offer versatility and flexibility in connecting tubes at different angles and configurations. By understanding the importance of sleeve couplers and how they are used in construction projects, we can appreciate their significance in creating a safe working environment for construction workers.

Key words:

Related Products