Contact Us

Tel / WeChat: +86-13832332178

Tel: +86 311 84396930

Email: sales@hanformwork.com

Whatsapp: +86-15097331922

Address No.1: Anjiazhuang Industrial Park Of Jinzhou City, Hebei Province, China

Address No.2: Room 1517, Building B, Xinhezuo Square, Xinhua District, Shijiazhuang City, Hebei Province, China

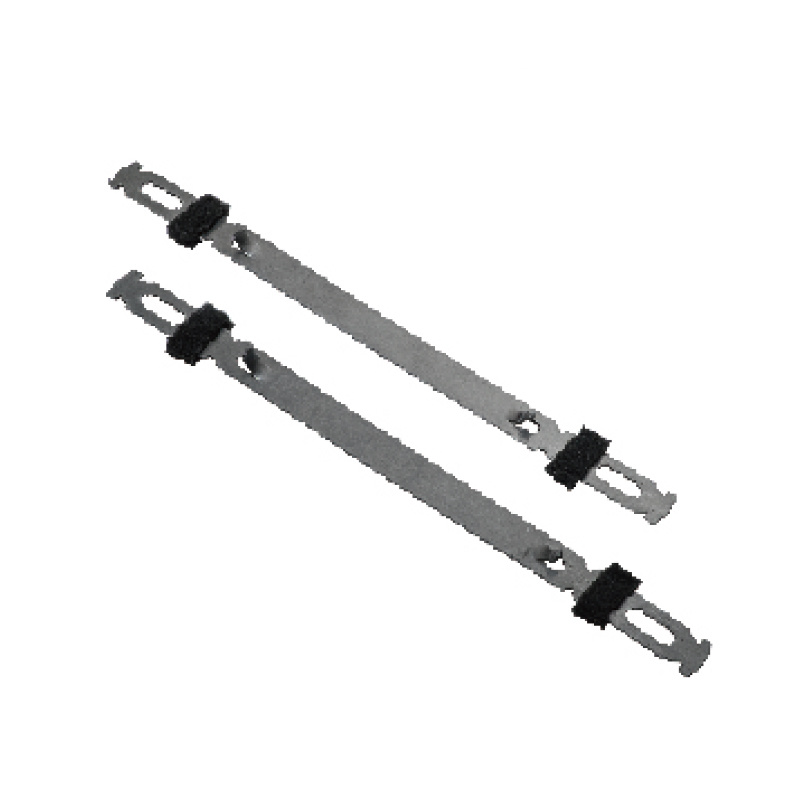

B Cone

- Commodity name: B Cone

- Product Description

-

Wooden formwork is a type of framework or mould that is used in construction to create concrete structures such as walls, slabs, columns, and beams. It is typically made from timber and is a popular choice due to its versatility, ease of use, and cost-effectiveness. In this article, we will explore the various advantages and disadvantages of wooden formwork, as well as some key considerations to keep in mind when using it in construction projects.

Advantages of Wooden Formwork

One of the main advantages of wooden formwork is its versatility. It can be easily cut and shaped to create complex shapes and designs, making it ideal for creating unique and customized structures. Additionally, wooden formwork is lightweight and easy to handle, which can help to reduce labor costs and increase efficiency on construction sites.

Another advantage of wooden formwork is its cost-effectiveness. Timber is a relatively inexpensive material, especially when compared to other types of formwork such as steel or aluminum. This can help to lower overall construction costs, making wooden formwork a popular choice for many builders and contractors.

Wooden formwork is also known for its good thermal and acoustic properties. Timber is a natural insulator, which can help to regulate temperatures inside buildings and reduce energy costs. Additionally, wooden formwork can help to absorb sound and reduce noise levels, creating a more comfortable and pleasant environment for building occupants.

Disadvantages of Wooden Formwork

Despite its many advantages, wooden formwork also has some disadvantages that should be taken into consideration. One of the main drawbacks of wooden formwork is its susceptibility to moisture and rot. Timber is a natural material that can warp, crack, and decay when exposed to water or high humidity levels. This can lead to structural instability and compromise the integrity of the concrete structure.

Another disadvantage of wooden formwork is its limited lifespan. Timber formwork is not as durable as steel or aluminum formwork and may need to be replaced more frequently, especially in harsh or corrosive environments. This can result in higher maintenance costs and downtime on construction sites.

Key Considerations for Using Wooden Formwork

When using wooden formwork in construction projects, there are several key considerations that should be taken into account. Firstly, it is important to properly treat and protect the timber to prevent moisture damage and decay. This can be done through the application of sealants, paints, or preservatives that can help to extend the lifespan of the formwork.

It is also essential to ensure that the wooden formwork is properly braced and supported to prevent deflection or collapse. Timber formwork can be prone to bending or bowing under the weight of wet concrete, so it is important to provide adequate bracing and reinforcement to maintain its structural integrity.

In addition, it is important to consider the environmental impact of using wooden formwork. Timber is a renewable resource, but deforestation and unsustainable logging practices can have negative consequences on the environment. It is therefore important to source timber from sustainable and certified sources to minimize the environmental impact of construction projects.

In conclusion, wooden formwork is a versatile and cost-effective option for creating concrete structures in construction projects. By understanding the advantages and disadvantages of wooden formwork, as well as key considerations for its use, builders and contractors can make informed decisions about incorporating this type of formwork into their projects. With proper care and maintenance, wooden formwork can be a durable and reliable option for creating high-quality concrete structures.

Key words:

Get A Quote

NOTE: Please leave your email, our professional person will contact you asap!

Related Products